Identificador: 2547

Abierta

ID de articulo : # 2547 se ha agregado a su lista de deseos.

Descripción

FINGER JOINT SEMI AUTOMATICA PARTE: 2CK-FL14

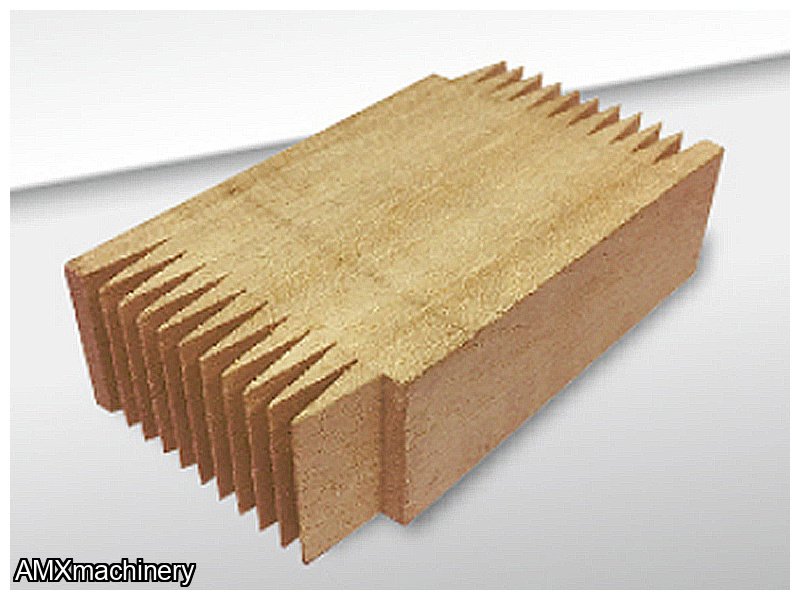

Represents a state-of-the-art finger jointing production line, meticulously crafted to transform extra short wood waste into valuable materials, all the while upholding an exceptional balance between performance and cost-effectiveness. Its compact design with multiple automatic features and options makes it an ideal solution for a small sized finger jointing operation. By utilizing a solitary shaper setup, this system delivers extraordinary value in performance and affordability, positioning it as an enduring revolutionary force within the woodworking sector.

- Semi-automatic finger jointer with a small footprint

- Excellent performance-to-cost ratio

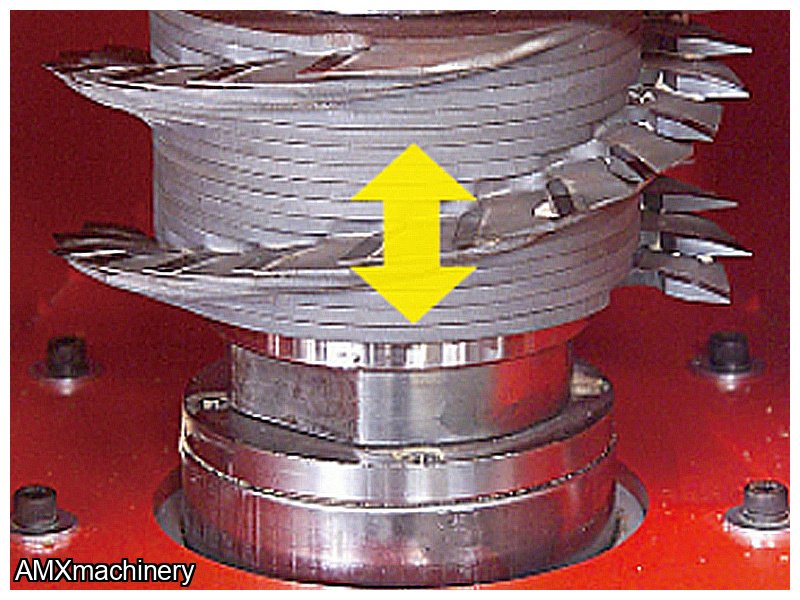

- Right/left finger shaper scores, profiles, and glues both right and left joints in a single machine

- Workpieces automatically travel between profiling & gluing stations

- Production speed: 2~3 cycles/min

- Length of cut is calculated by an encoder and set on a touch screen for increased accuracy with a finished board tolerance of 0 to 0.08” (0 to 2mm)

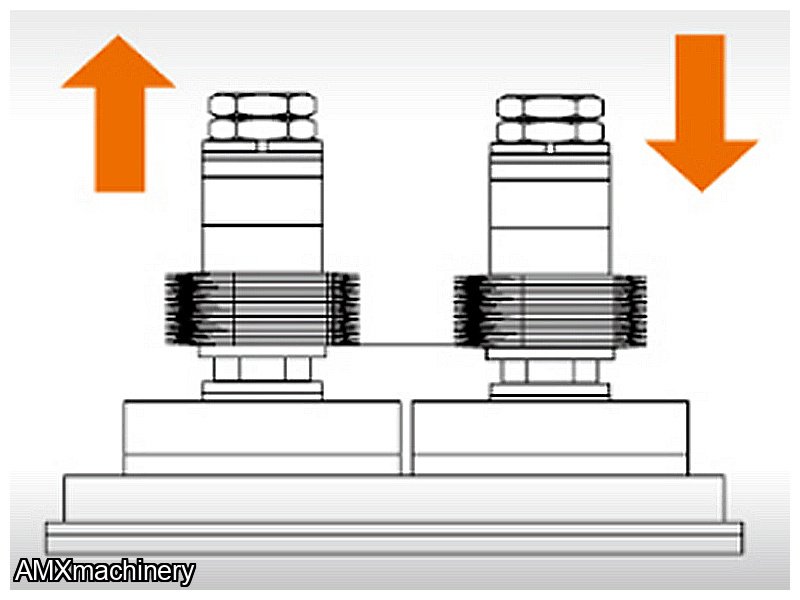

- Manual rotary table design turns pieces to allow processing of both ends on a single shaper system – optional automatic rotary table available

- Optional automatic adjustment of the scoring blades and shaper section for left & right profiles

- Presses available in various lengths to suit your production needs

- Applicable for machining extra short wood waste of 4” (100mm)

- Only two operators required for max production

- Hopper loader mounted for workpieces to automatically feed into the assembly press comes standard with the FL-24

- As standard we use PVAc glue, but we have optional gluing systems for PUR, MUF, EPI, etc. available upon request

- Synchronized jointing and length cutting is performed in a 2-step process within the F-A05 or A07 single stage automatic infeed finger assembler

Includes the following:

F-C03W01 Finger Shaper (Injection Glue System)

DESCRIPTION | |

Max. available width working table | 650 mm (25.6”) |

Range of workpiece length | 100~1000 mm (4.7~27.5”) |

Range of workpiece width | 20~60 mm (3.9~39.4”) |

Range of workpiece thickness | 30~160 mm (1.2~6.3”) |

Trimming saw speed | 2800/3400 RPM |

Finger cutter speed | 6000 RPM |

Finger cutter diameter (in/out) | ø70 / ø160 mm (ø2.8 / ø6.3) |

Dust out diameter | 6 x 2” |

Machine dimensions (L x W x H) | 4425 x 1815 x 1855 mm (175 x 72 x 73”) |

POWER REQUIRED | |

Table-drive motor (Infeed & Outfeed) | 1/2 HP x2 |

For conveyor motor | 1/2 HP x2 |

Scoring saw motor (Top & Bottom) | 2 HP |

Trimming saw motor | 5 HP |

Shaper cutter motor | 15 HP |

* 1: Injection type glue applicator – using PVAc glue only

* 2: Finger cutters – 10 pieces

* 3: Comes with saw blades

F-D06-1.4 Roller Table

DESCRIPTION | |

Pago y Devoluciones

- Forma de pago

- N/A

Publicar mensaje

Ingresar to ask the seller a question.

AMXmachinery1

TORNO 32 x 120''

TORNO 32 x 120'' PARTE: 2GM-GML-32120Heavy Duty Precision Gap Bed Lathe 32” x 120” 4-1/8” bore, 15HP Motor.ISO 9001 certifiedLarge spindle bore 4-1/8”4-way rapid traverse on Longitudinal and cross waysAll dual inch/metric dials. solid cast iron machine baseHeavy Duty main motor 15 HP12 spindle speeds from 25-1,600 rpm54 kinds of inch threads and metric threadsThreading and feeding rate change by leversSpindle is balanced, hardened and precision groundSpindle is supported a...

AMXmachinery1

MESA DE TIJERA - 3' x 6'

PARTE: 2CK-PH36-2 - MESA DE TIJERA - 3' x 6'Is strongly built with a massive steel frame that provides maximum durability and is capable of lifting up to 4400 lbs. It is hydraulically operated and controlled by a foot pedal for operator convenience. The PH36-2 is adjustable in height from 12” up to 59”. It is ideal for staging material for feeding into various woodworking machines like sanders, glue spreaders, panel saws, ripsaws, and more.4400 lifting capacity3’ x 6’ deck size12”...

AMXmachinery1

SIERRA MULTIPLE - DIAMETRO DISCOS 12”

PARTE: 2NT-NT-MRS12N - SIERRA MULTIPLE - DIAMETRO DISCOS

12”The NT MRS12N Multiple Rip Saw features a cast iron frame that houses a variable speed dip chain for premium rip capability. Often referred to as gang rip saws, this machine is fitted with closer fitting upper hold down rollers the MRS12N boasts the shortest part feeding on a multiple rip saw. The MRS12N uses 12″ diameter rip saw blades and can be equipped with power raise and lower, invertor speed control and non marking urethane ...

AMXmachinery1

SIERRA DOBLE - 45 GRADOS - 20 PULGADAS

PARTE: 2CK-PCM508Is a precision pneumatic saw designed for cutting miters up to 60o in either direction. The saw is automatically cycled pneumatically and activated by a foot switch to allow for fast positioning of the workpiece. Capable of production cutting with up to 40 cuts per minute. The cutting speed is adjustable to ensure the optimum finish result on your workpiece no matter the species or size. The rotary table runs on ball bearings to ensure effortless rotation of the blade ...

-500x500.png)

-500x500.png)