Descripción

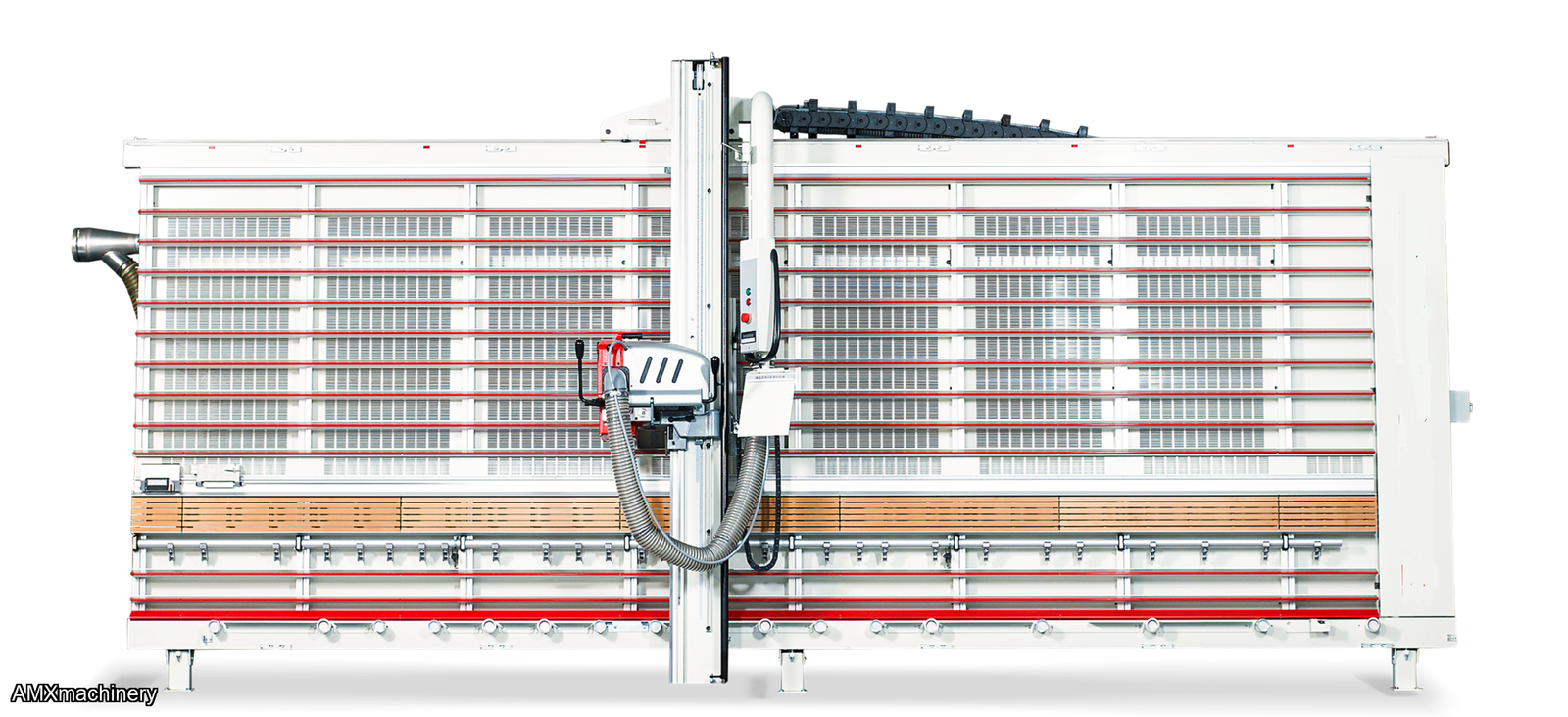

PARTE: 2ST-COMPACT - SIERRA ESCUADRADORA VERTICAL - COMPACT - CAP. 122” X 65” X 2-3/8”

NUEVA CON GARANTIA

• 5’5” x 10’2” cut capacity; 2-3/8” (60mm) cut depth

• 5-1/4hp, 3-ph high-efficiency motor w/ electro-mechanical brake

• One-piece full-length centershelf with moveable aluminum fingers

• Integral full-length wood support area for small part support

• Specially designed measuring stop for use w small parts

Flexible and Economical

The STRIEBIG COMPACT is the entry level into the world of precision and quality of STRIEBIG vertical panel saws.

The Compact is designed to meet the needs of users who require a smaller vertical panel saw for all their sizing cuts. Each Compact is equipped with all the typical features of a Striebig high-performance saw. It goes without saying that almost the entire range of standard accessories can be used on this machine.

Apart from its size and power output, it is just as universal in use as all the other Striebig panel saws.

Small, full-featured saw at an affordable price

The Compact is the ideal machine wherever a modern, space-saving panel saw is required. It can saw anything and, thanks to its versatile range of accessories, is equally suited to handling universal as well as special jobs at an affordable price.

A Compact will cut perfect edges on particle board, acrylics, composites, plastic and non-ferrous metal panels to an accuracy of 1/10 mm. It is thus the ideal machine for many workshops that regularly need to cut these materials.

You can measure and cut to an accuracy of 1/10 mm on a Compact with the digital measuring system (option). Additionally, the support rollers which are aligned and ground to a precision of 1/100 mm on all saws are a further guarantee of Striebig's unlimited measuring precision.

Features & Benefits

• One-piece fully welded frame, able to floor or wall-mount.

• 10’2” x 5’5” cut capacity; 2-3/8” cut depth

• Heavy-duty support rollers with integral panel stop

• Full-length mid-shelf with adjustable spacing for aluminum fingers and built-in wood small parts support area

• Auto, upward-shifting aluminum support grid w/plastic laths

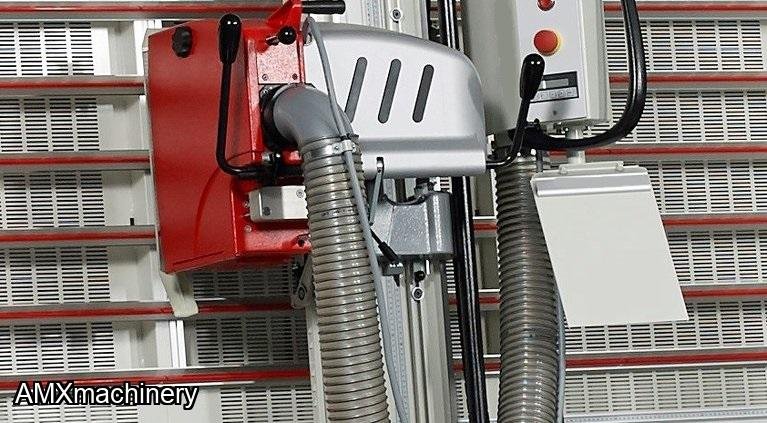

• NEW highly efficient dust system, enclosed in cable chain

• 5-1/4hp, 208-480V, 3 motor with electric brake

• 250mm carbide saw blade for 2-3/8” depth of cut

- Specially designed measuring flip stop for use with small parts

• Template bar accepts optional stops for common rip cuts

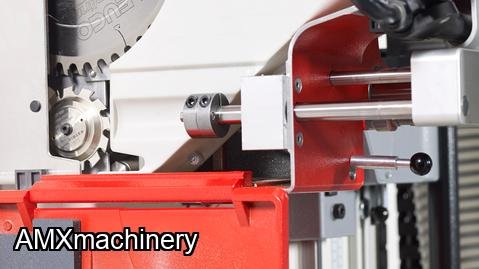

• Optional true split-blade scoring saw available (& retrottable)

• Optional locking rollers, foot-pedal operated (factory ordered)

Specifications

Cut capacities: 10'2" W x 5'5" H; depth 2-3/8" (60mm)

Weight (approx.): 1100 lbs. (net), 1600 lbs. (gross)

Main Saw Blade: 250 mm dia., 30 mm bore with (2) 7 mm pin holes (42 mm circle)

Scoring Saw Blade: (option) 80 mm dia., 20 mm bore split-blade type w/shims

Electrical: 3 phase, 220V/20 Amp or 440V/10 Amp service *208V and 280V motors available

Dust collection: 1000 cfm, 100 (x2)mm connections (second connection at bottom right corner of frame is optional and hose is not provided.)

Accessories

• DMS Digital measuring system for both X and Y axes

• VSA Scoring saw unit; split-type blade with shims or adjustable width

• WSG Angle cutting attachment

• ACM aluminum composite panel grooving kit and insert-type profile cutters for 90/135/U-shape bends

• Dado/profile grooving depth stop kit and carbide insert cutting tools

• Locking rollers (foot-pedal operated)

• Carbon-fiber center shelf support fingers for sensitive panel edges

• Repeat rip device with 25” scale for top-down strip cutting

• Snap-in aluminum small parts supports

• Removable clipboard mounted underneath operator control panel

• Template bar stops (program cams) to set common rip cut dimensions

Compact Options:

VSA Scoring Unit

Digital Measuring System

WSG Angle Cutting Device

Standard Measuring Flip Stop

Dado Cutting

ACM Cutting & Grooving

Pago y Devoluciones

- Forma de pago

- Transferencia/Deposito Bancario