Descripción

PARTE: 2TA-PT-48HF – PRENSA DE TABLEROSD - ALTA FRECUENCIA – ALTA PRODUCCION – CAPACIDAD 49” X 98”

New with warranty

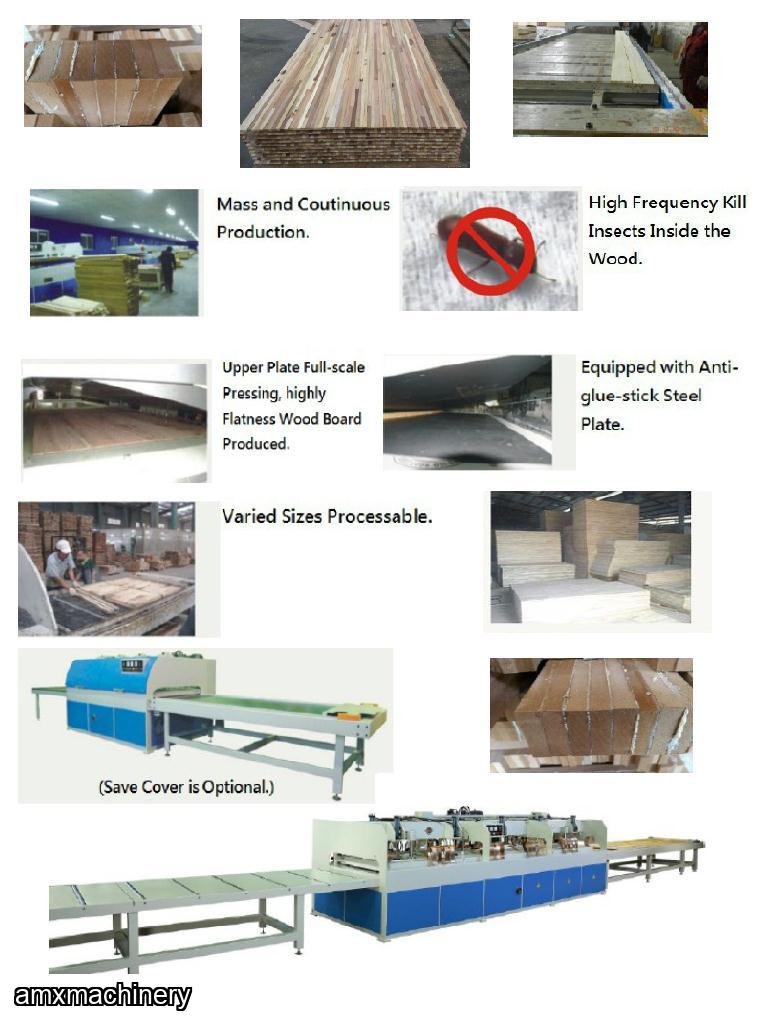

Mass production for wooden board, 2 to 3 minute for drying a 4' x 8' wooden board

Automatic infeed, out-feed cycle, mass production within 3 - 5 minutes is ready for output.

Shortens manufacturing procedures – no need to pass through for the dovetailing or joining process.

Equipped with a massive upper plate supplies powerful hydraulic pressure, which presses each part of wood board to make even the most crooked pieces of wood flat.

Due to the flatness it has made, there is may not needs to pass through double side planer processing. This substantially reduces wood loss.

User friendly operations; it is equipped with side automatic inlet and outlet feeding table system for continuous and mass production.

Top quality wood board is manufactured by way of glue cured and completely hardened glue joins with high frequency heating in the meantime.

All processing steps are integrated into the HMI interface control panel for easy one-touch control on the screen.

Utilizes high frequency, glue cured evenly from inner of the glue line of the wood.

Model No. | 2LB-PT-48HF |

In Put Power | 40 KVA |

Out Put Power | 30 KW |

Max. Working Width | 49" |

Max. Working Length | 98" |

Working Height | 9/16" ~ 3-1/8" |

Pressure | 65 kg/cm2 |

Hydraulic Pump | 5 HP |

Press Cylinder (top) | 4 Pcs |

Press Cylinder (Rear) | 12 Pcs |

Out Feed Rollers | 5 Pcs |

Machine Size | 307" x 87" x 87" (L x W x H) |

Machine Weight | 12700 LBS |

Pago y Devoluciones

- Forma de pago

- Transferencia/Deposito Bancario